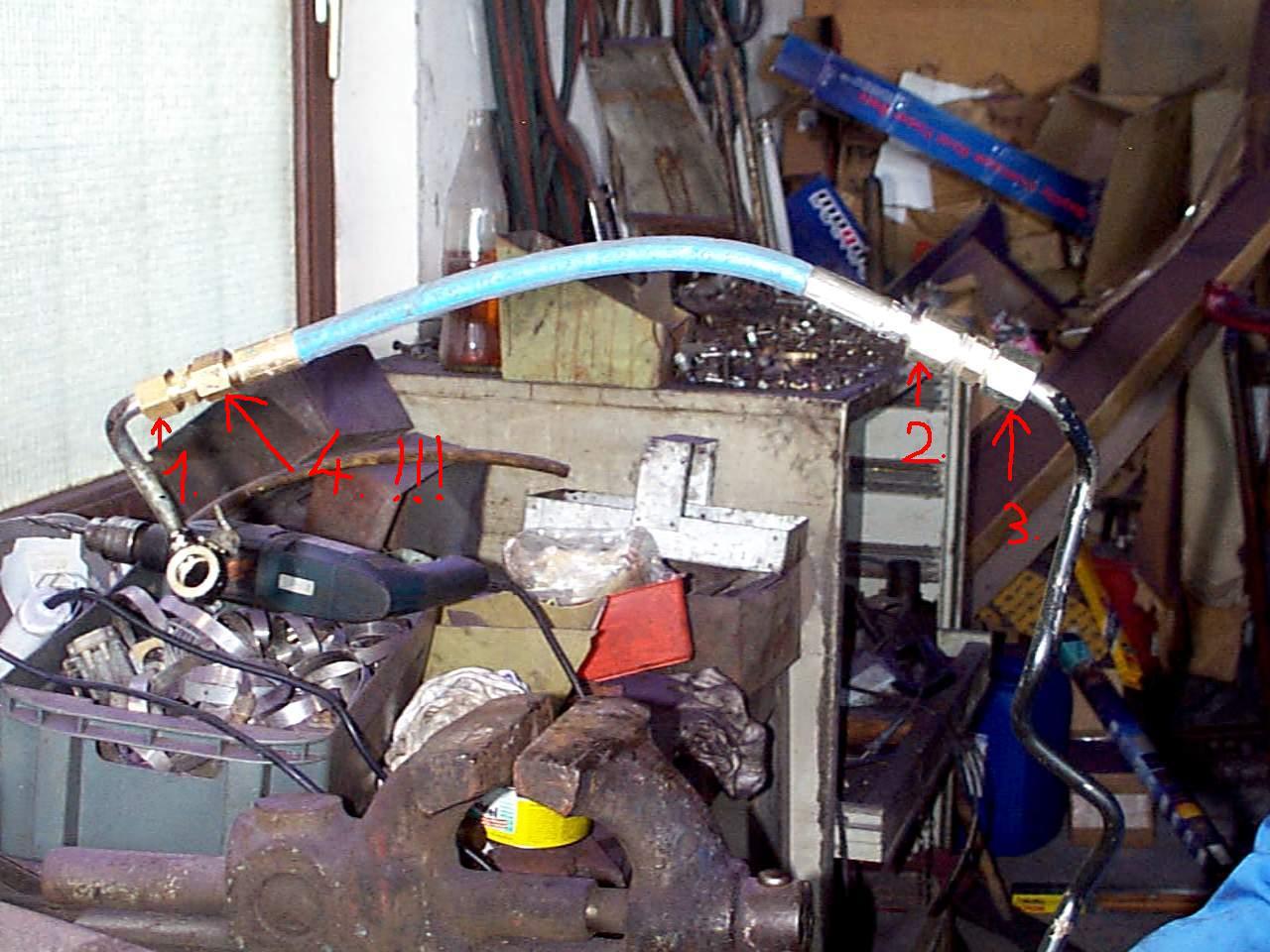

To the picture above:

1. The replacement of this hose is described in this manual

2. this clamp must be removed (SW 8)

3. this clamp must also be removed (SW 10)

4. Remove the banjo bolt on the steering gear and pay attention to the seals

5. Remove the banjo bolt on the servo pump and pay attention to the seal

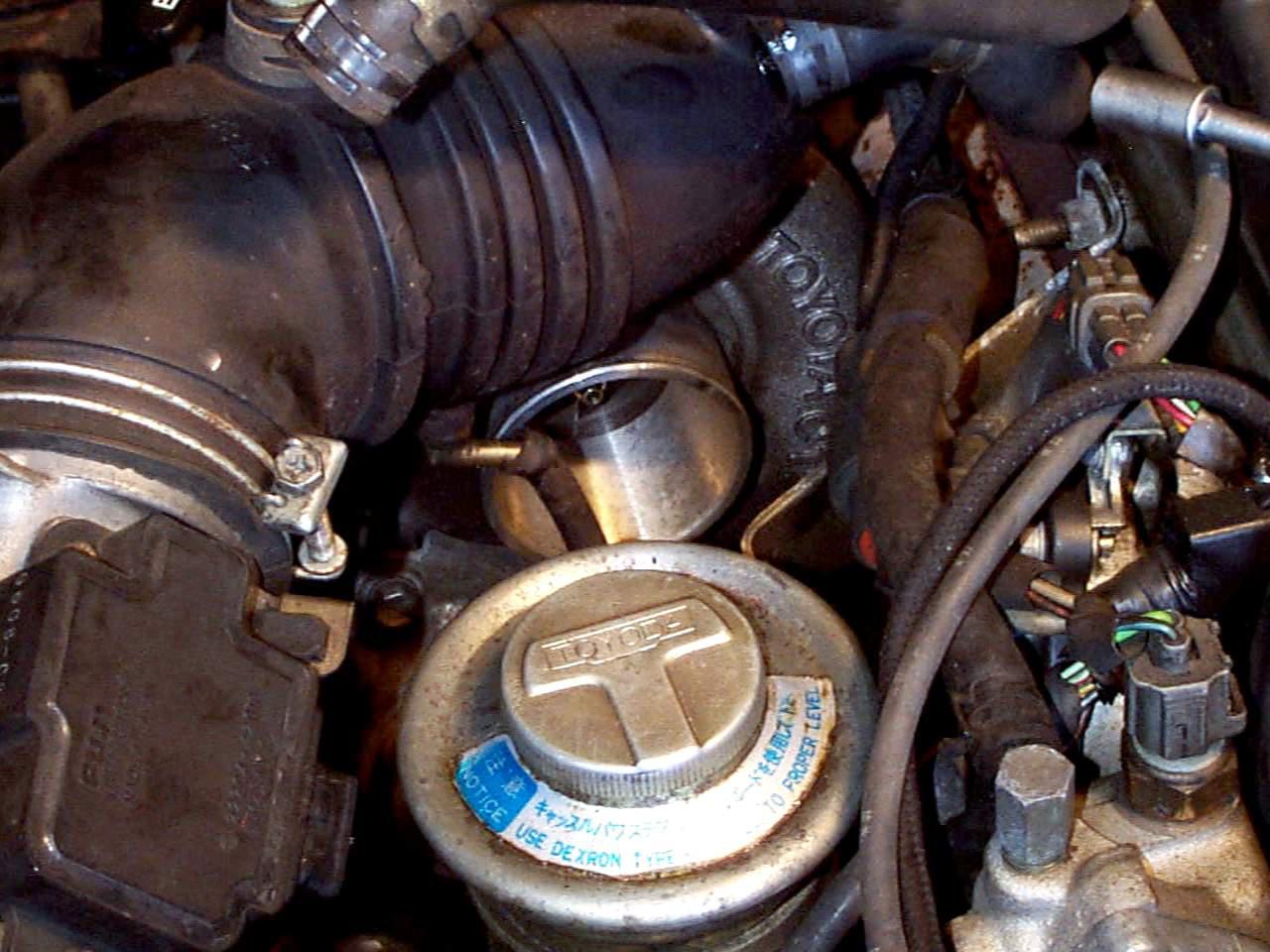

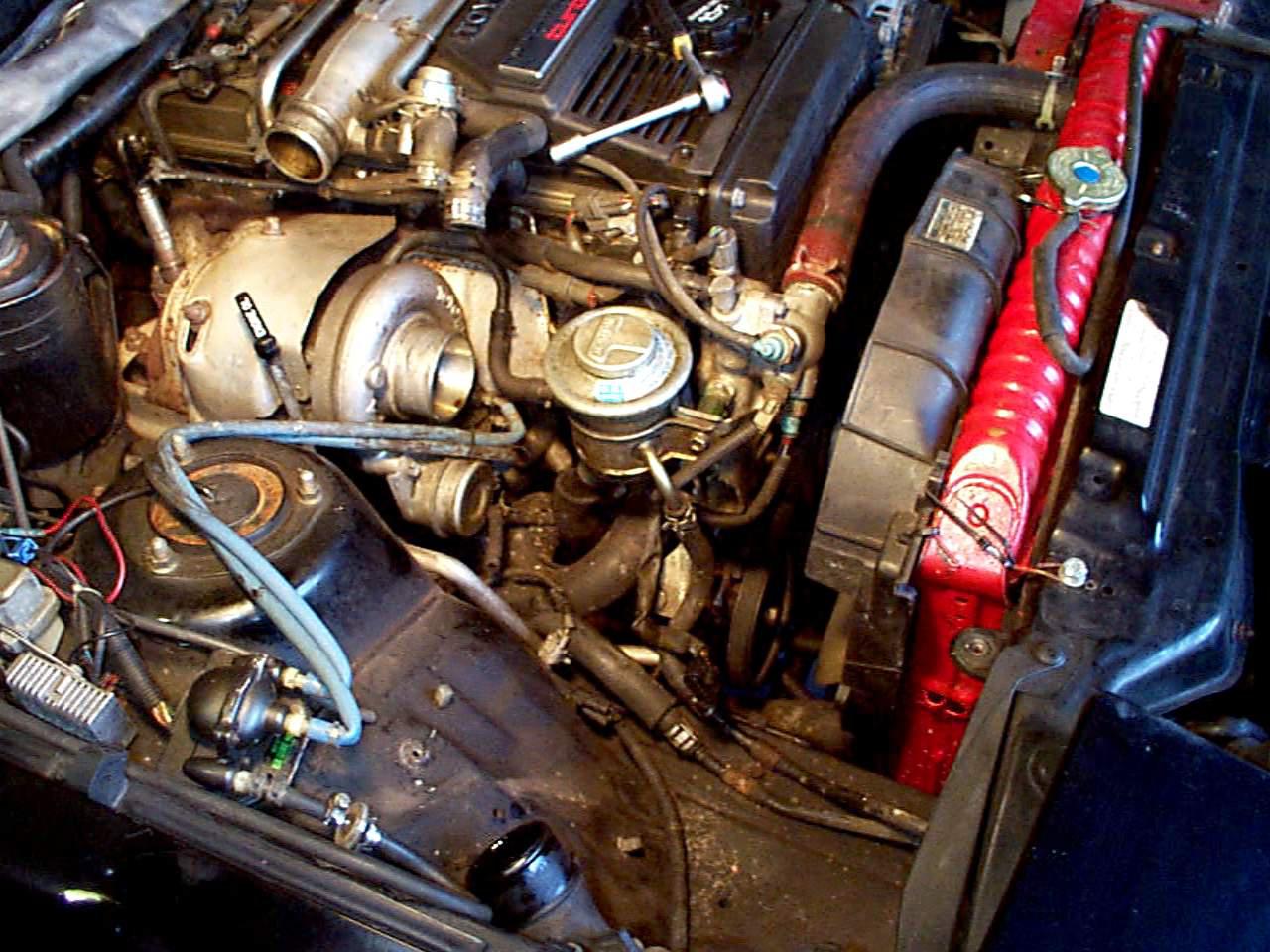

This is what it should look like after the conversion

Expansion hardpipe

Removing air filter and intake manifold

Pay attention to the small hose! and disconnect the cable from the LMM

Should look like that

Remove banjo bolt on servo pump, hold screw with wrench

Attention, place the vessel!

Disconnect hoses from servo oil cooler lines

Attention, place the vessel!

Remove clamp no. 2 and clamp no. 3 as shown in exploded view, and remove banjo bolt no. Attention, place the vessel!

The line should then be loose

Pull the wire down as far as possible, making sure that the pipes are not bent !!!

Now you can cut the broken hose with the iron saw or Flex

Saw off the tube directly at the pressure of the tube, do not use Flex !!!

Deburr the pipe at the cut surface

Deburr the pipe from the inside with a drill

Sand the pipe with sandpaper

The whole thing we do at the other end of the defective hose just like that.

Both pipe ends should look like this

Clean both pipes from the outside and blow out with compressed air

Placing the screw connections

The pipe must be inserted into the fitting until it stops and then tightened

We do the same with the other end of the line

Fastening 1. / 2. / 3. can be tightened, screwing 4. not !!!! tighten

The line should look like this

Thread the line from below back into its original position

The new hose should then be here to watch

According to the exploded view, re-install the servo cable on the steering box with the banjo bolt and the gaskets, and refit the 2 holders of the servo lead.

Mount the tube piece on the new tube and align it so that it can be mounted on the servo pump without twisting the servo tube, then tighten this screw connection.

Mount the servo cable with banjo bolt and seal on the servo pump. Make sure that the servo tube is not twisted and lies in a nice bow, it must not be sharply kinked, if that should be the case, the line must be bent slightly.

Now you can reassemble the rest in reverse order. Fill the servo oil reservoir with Dextron II and start the engine, then move the steering wheel from side to side several times until it stops. Any abnormal noises of the servo pump are normal, since only the air must escape from the system. If there are no more bubbles in the servo oil tank, check the oil level and adjust if necessary. Then you should remove the old oil, which was distributed by the defective hose generously in the engine compartment with a suitable agent (brake cleaner).

Have fun screwing.

Sincerely, GM Turbo